Engineering

Sewing Machines and Pudding

In seventh grade while taking the required home economics class – standard for all girls in those days – my classmate’s sewing machine jammed. I spent the class enthusiastically taking apart the machine and reassembling it to work correctly. The teacher was understandably not appreciative that a 13 year old fiddled with an expensive piece of school equipment. I was also unable to make an edible cornstarch pudding in the class, which begs the question – is any cornstarch pudding edible? I did, however, really enjoy the “innovative and modern experiment” of a six-week shop class for us girls (during which, destined to become fine homemakers, we made cutting boards and a rolling pin).

In seventh grade while taking the required home economics class – standard for all girls in those days – my classmate’s sewing machine jammed. I spent the class enthusiastically taking apart the machine and reassembling it to work correctly. The teacher was understandably not appreciative that a 13 year old fiddled with an expensive piece of school equipment. I was also unable to make an edible cornstarch pudding in the class, which begs the question – is any cornstarch pudding edible? I did, however, really enjoy the “innovative and modern experiment” of a six-week shop class for us girls (during which, destined to become fine homemakers, we made cutting boards and a rolling pin).

Pumps, Toys, and Medical Devices

When I graduated from college with an engineering degree (my father was aghast and had loudly suggested that I become a secretary for a “real” engineer), I immediately went to work for a company that made cleaning chemicals used in restaurants and hospital laundries.  My department designed variations of a “pump in a box with a switch” to dispense the detergents, and I fell into a depression, bored to death, ignored or ridiculed by the men and certain that I had chosen the wrong career.

My department designed variations of a “pump in a box with a switch” to dispense the detergents, and I fell into a depression, bored to death, ignored or ridiculed by the men and certain that I had chosen the wrong career.

Luckily for me, I found a job in the toy industry, and became an expert in injection molded plastic design. OK, I know that not everyone would say they were lucky to have become an expert in injection molded plastic design, but I liked it. Schaper Toys, and later Tonka Toys were full of young, energetic and eccentric people, and I loved seeing kids play with toys I had engineered.

After moving to Seattle, I ran the mechanical engineering department of a company that did design and manufacturing of medical devices for customers ranging from mega-companies down to one-person startups. This work was rewarding as well (despite a few devices that made me scratch my head and wonder “why?”), and I felt lucky to work for a great company, designing and building things that helped people.

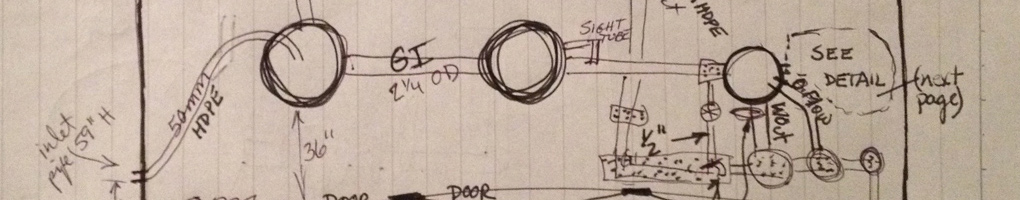

Engineers Without Borders

Years later, after I had left engineering and been a musician for a while, someone mentioned Engineers Without Borders to me, which I had never heard of. I looked into it, joined the organization, and learned a lot having nothing to do with injection molding and everything to do with water supply and that pesky question of human waste. I spent a dozen years working in Nepal on rural water supply systems, managing projects and people and using my engineering in the most rewarding way possible. Few experiences can surpass seeing water come out of a new tap in a village that has never had running water. Once again, I am lucky.